Every driver knows the feeling—a sharp ping as a pebble strikes the hood or fender. Over time, these tiny impacts leave visible chips and scratches that slowly wear down your vehicle’s finish. These imperfections might seem small, but they mark the beginning of deeper surface degradation caused by exposure, oxidation, and continued friction from road debris.

At LINE-X AUTO SPA, understanding why paint protection film (PPF) performs so well against rock chips and debris isn’t just a matter of experience—it’s about material science. Behind that thin, invisible layer is a world of engineering that combines chemistry, elasticity, and energy absorption to protect modern automotive surfaces with scientific precision.

Understanding How Vehicles Face Everyday Surface Damage

On any road—highway, gravel, or city street—tiny stones, sand, and debris are constantly flung toward a vehicle’s paint. Each impact transfers kinetic energy that can fracture the clear coat, chip paint, or expose metal to corrosion.

Traditional paints and clear coats, though durable, are rigid by nature. They lack the flexibility to absorb shock. Paint protection film bridges that gap, creating a dynamic barrier that disperses energy instead of allowing it to damage the paint.

The Role of Paint Protection Film in Modern Automotive Science

PPF represents a fusion of polymer chemistry and mechanical engineering. Designed to stretch, absorb, and recover, the film acts like a transparent shield that moves with the surface it protects. It’s not paint, and it’s not coating—it’s a multi-layered composite that uses physical science to solve real-world problems vehicles face daily.

What Causes Rock Chips and Surface Damage

The Physics of Impact Energy on Vehicle Paint

When a rock strikes a car, kinetic energy is instantly transferred to the point of impact. Because paint and clear coats are brittle, they can’t flex or redistribute the energy, so it cracks or chips. The sharper or heavier the debris, the deeper the penetration.

How Road Debris Interacts with Clear Coats

Paint systems rely on hardness for protection, but that same rigidity becomes their weakness. Once the clear coat fractures, moisture and oxygen seep in, leading to corrosion, oxidation, and long-term paint failure. That’s why engineers looked toward flexible polymers for a better solution—hence, the rise of Paint Protection Film Riviera Beach FL.

The Composition of Paint Protection Film

The Multi-Layer Structure Explained

A modern PPF is made of three main layers:

- Top coat: a self-healing, UV-resistant layer that resists scratches and oxidation.

- Middle layer: a flexible, impact-absorbing polyurethane core.

- Adhesive base: a pressure-sensitive layer that forms a permanent yet removable bond to the paint.

The Role of Thermoplastic Urethane (TPU) in Flexibility

TPU is the backbone of the film. This polymer can stretch under stress and return to its original form once the force is removed. That elasticity is what makes PPF absorb impacts rather than crack under pressure.

The Science Behind Impact Resistance

How Paint Protection Film Absorbs and Disperses Energy

When debris hits, the PPF’s middle layer compresses, absorbing the energy like a cushion. The force spreads across the film rather than focusing on a single point. This distribution minimizes the likelihood of paint chipping or surface indentation.

Why Elastic Recovery Prevents Paint Chipping

Elastic recovery allows the film to return to its original shape after deformation. This “memory” effect keeps the film intact while preserving the smooth surface beneath. In physics, this behavior is known as reversible strain—a property TPU excels at maintaining.

Adhesive Technology and Surface Bonding

The Function of Pressure-Sensitive Adhesives

The adhesive layer in PPF isn’t just glue—it’s engineered to form microscopic bonds with the paint’s clear coat. These molecular interactions create uniform adhesion, preventing air gaps and ensuring even protection across the surface.

Maintaining Stability Under Stress and Temperature Fluctuations

Adhesives must perform under a wide temperature range. Whether it’s a summer day or winter frost, paint protection film maintains a stable grip without lifting, peeling, or bubbling. This reliability is due to heat-resistant polymers that expand and contract in harmony with the vehicle surface.

Material Engineering and Polymer Science

Cross-Linking and Molecular Strength

PPF polymers are cross-linked, meaning their molecular chains are connected in multiple directions. This structure increases tensile strength and resists tearing while maintaining elasticity—a key factor in protecting against sharp debris.

The Relationship Between Film Thickness and Durability

A film’s effectiveness often depends on its thickness. Thicker films absorb more energy but can reduce optical clarity if poorly engineered. High-quality films balance thickness and transparency through advanced extrusion processes that maintain consistent density.

How Paint Protection Film Withstands Repeated Impacts

The Concept of Elastic Deformation

Each impact slightly deforms the film. Instead of cracking, PPF stretches at the molecular level, dispersing the force outward. This microscopic flexibility prevents structural damage that paint alone could never withstand.

Fatigue Resistance and Long-Term Protection

Over time, repeated impacts could weaken most materials, but PPF’s cross-linked polymers resist fatigue. They can handle countless small strikes without breaking down, maintaining performance year after year.

Self-Healing Technology in Paint Protection Film

How Heat Reactivates Polymer Memory

When light scratches occur, mild heat—from sunlight or warm water—causes the film’s polymer chains to shift back into alignment. This “memory” feature restores the surface’s smoothness without manual intervention.

The Chemical Mechanism of Scratch Recovery

The top coat contains elastomers that soften when heated, allowing displaced molecules to move and fill minor abrasions. Once cooled, the film regains hardness, leaving behind a clear, uniform surface.

Environmental Factors Influencing Performance

UV Radiation and Oxidation Resistance

Prolonged sunlight exposure can cause oxidation in many materials. PPF counteracts this with UV absorbers and stabilizers that convert harmful radiation into harmless heat, protecting both the film and the underlying paint.

How PPF Maintains Clarity in Harsh Conditions

Through anti-yellowing additives and optical stabilizers, paint protection film resists haze formation. These compounds preserve transparency even after years of exposure to sun, rain, or airborne pollutants.

Laboratory and Real-World Testing of Paint Protection Film

Impact and Weather Simulation Studies

Manufacturers test films through accelerated weathering—using high-velocity impact machines, UV chambers, and salt sprays to simulate years of exposure. These tests assess tensile strength, gloss retention, and adhesion.

Field Observations and Data from Real Driving Conditions

Vehicles equipped with PPF in varying climates—from deserts to snow-covered regions—provide measurable data. Results show up to a 90% reduction in visible paint chips compared to unprotected surfaces.

Advances in Paint Protection Film Engineering

Nano ceramic Additives and Infrared Reflection

Next-generation PPFs use nano ceramic particles that reflect infrared radiation, reducing surface temperature and improving UV protection. These particles also reinforce the polymer network, enhancing scratch and heat resistance.

Future Innovations in Smart Adaptive Films

Researchers are developing adaptive films that modify their stiffness based on temperature or impact levels. These “smart” materials represent the next phase of protection technology, making surfaces more responsive to environmental stress.

Comparing Paint Protection Film to Traditional Clear Coats

Why Paint Alone Cannot Handle Repeated Impact Stress

Clear coats harden for gloss and chemical resistance, but their rigidity causes micro-cracks under stress. Once damaged, the surface can’t repair itself and continues to deteriorate.

How PPF Provides a Mechanical Advantage

PPF’s flexible construction allows it to move with the surface, absorbing energy rather than resisting it. This mechanical advantage is why it’s widely adopted across industries—from automotive to aerospace.

The Role of Science in Automotive Surface Preservation

How Chemistry and Physics Work Together in PPF Design

PPF succeeds because of its interdisciplinary design. Chemistry contributes molecular stability, while physics governs elasticity and energy transfer. Together, they create a product that’s both flexible and strong.

Why Research Matters for Long-Term Vehicle Protection

Continuous research ensures films maintain optical purity, adhesion, and mechanical strength over time. Advances in polymer engineering continue to redefine what surface protection can achieve in the automotive field.

LINE-X AUTO SPA Serving the Community Spencer Lakes and Beyond West Palm Beach, FL

LINE-X AUTO SPA is dedicated to serving the diverse needs of the local community of West Palm Beach, FL, including individuals residing in neighborhood like Spencer Lakes With its convenient location near landmarks such as the ” HCA Florida JFK North Hospital, Palm Beach Harley-Davidson” and major intersections like 45th St & I-95 Interchange and Village Blvd & I-95 access road (coordinates: 26.753427, -80.092092), We offer paint protection film services.

Get Paint Protection Film Services at Spencer Lakes Now

Navigate from Spencer Lakes to Line X Auto spa Now

What Makes Paint Protection Film Effective Against Rock Chips and Debris?

- 40% of vehicles suffer rock chip damage over their lifespan; PPF reduces paint chips and scratches by up to 50%, acting as a durable sacrificial shield.

- Made from thermoplastic polyurethane (TPU), PPF’s elasticity absorbs and disperses impact energy from stones and debris, preventing paint chipping.

- Self-healing topcoat enables minor scratches to disappear with heat (sunlight or warm water), maintaining flawless appearance over years.

- Compared to ceramic coatings, PPF offers superior physical abrasion resistance, protecting critical areas like hoods, bumpers, and mirrors.

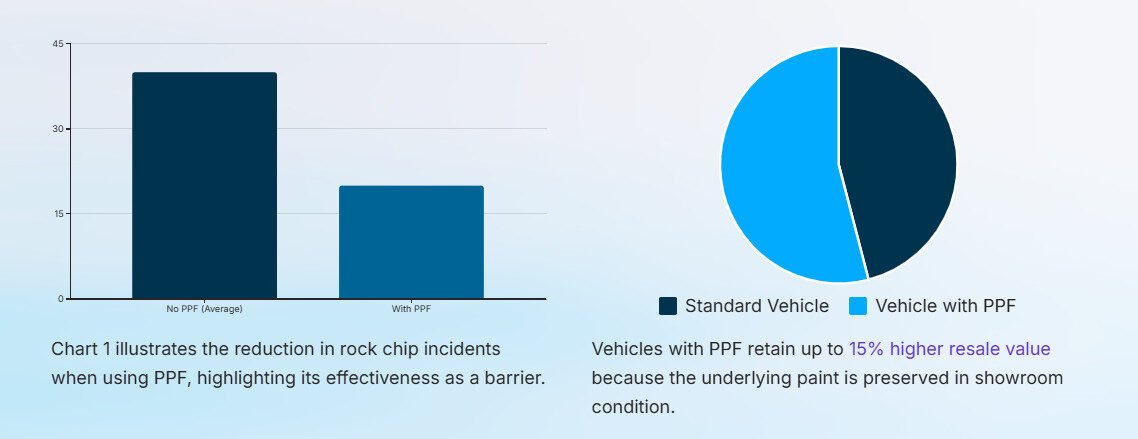

- Vehicles with PPF retain up to 15% higher resale value due to preserved paint integrity and reduced repair costs.

- Chart 1: Rock Chip Incidence — 40% (No PPF) vs. 20% (With PPF)

- Chart 2: Resale Value Retention — Average vehicle vs. Vehicle with PPF (+15%)

- Chart 3: Impact Absorption Mechanism — TPU film stretching vs. brittle clear coat cracking

Sources: Topline Auto Spa (2025), EveryDetailMe (2025), Garvin Auto (2025), ClearPro (2025) [Visuals: Side-by-side images of car panels with and without PPF showing chip damage; schematic of TPU film flexing under impact]

What makes paint protection film effective against rock chips and debris is not magic—it’s science. Every layer, molecule, and reaction is engineered to protect paint surfaces from impact, heat, and oxidation. It bends instead of breaks, absorbs instead of transfers, and repairs instead of deteriorating.

At LINE-X AUTO SPA, understanding the materials behind PPF reveals its role as a genuine innovation in automotive care. It’s a quiet but powerful example of how modern engineering and material science can preserve what drivers value most—the integrity and beauty of their vehicles.

FAQs

How does paint protection film prevent rock chips?

The film absorbs impact energy and spreads it across its surface, reducing concentrated force and preventing chips.

What makes PPF better than clear coats?

Clear coats are rigid and crack under stress, while PPF is flexible, self-healing, and capable of absorbing impact.

How long does paint protection film remain effective?

High-quality films can perform effectively for many years, maintaining clarity and adhesion with minimal maintenance.

Can PPF handle extreme heat or cold?

Yes. Its thermoplastic properties allow it to expand and contract without losing grip or forming bubbles.

Does paint protection film need any special care?

Gentle washing and avoiding harsh chemicals preserve its optical clarity and self-healing properties over time.